Remanufactured collision parts provide a cost-effective and sustainable option for vehicle repairs after accidents. These used but restored components undergo rigorous inspection, disassembly, cleaning, replacement of worn parts, and reassembly to meet new quality standards. Reputable suppliers guarantee performance and offer detailed information on the remanufacturing process. When evaluating these parts, a keen eye for detail is crucial, focusing on surface wear and precise fitting. Advanced testing methods like X-ray fluorescence spectroscopy and ultrasonic testing ensure material composition, structural integrity, and performance capabilities. Reputable collision repair centers use comprehensive quality assurance protocols and computer-aided design (CAD) software to guarantee visual perfection and structural soundness in repairs.

In today’s automotive landscape, remanufactured collision parts are gaining popularity as a sustainable and cost-effective solution. However, ensuring their authenticity is paramount to prevent unsafe and substandard repairs. This article guides you through the process of verifying the authenticity of these parts, offering insights into understanding remanufactured collision parts, key indicators of genuine products, and robust testing methods for quality assurance.

- Understanding Remanufactured Collision Parts

- Key Indicators of Part Authenticity

- Testing Methods for Quality Assurance

Understanding Remanufactured Collision Parts

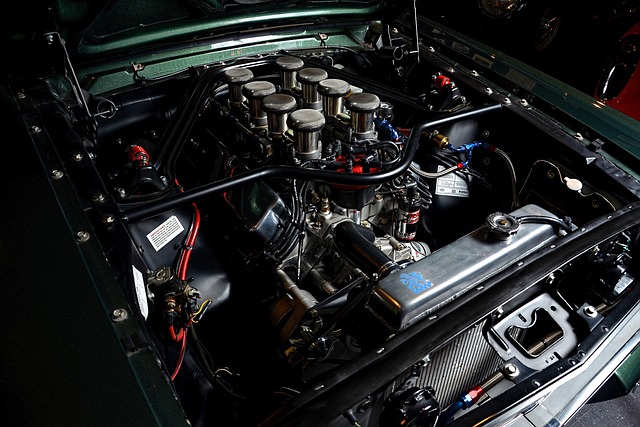

Remanufactured collision parts are a cost-effective solution for vehicle owners looking to repair their cars after an accident. These parts are essentially damaged or used components that have been thoroughly inspected, restored, and reconditioned to meet specific quality standards. The process involves careful disassembly, cleaning, replacement of worn-out parts, and reassembly, ensuring they function like new again. This not only reduces costs but also provides a sustainable alternative to replacing entire vehicles or buying brand new parts.

Understanding what these parts entail is crucial for consumers. Reputable suppliers will provide detailed information on the remanufacturing process, including the specific make and model of the original part used. It’s important to differentiate remanufactured collision parts from used or refurbished ones, as the former undergo more rigorous quality checks and are guaranteed to perform like new vehicles, offering peace of mind for those undertaking repairs, whether it’s a fender repair, bumper repair, or dent removal.

Key Indicators of Part Authenticity

When assessing remanufactured collision parts, several key indicators can help verify their authenticity and quality. Start by examining the part’s surface for any signs of wear or inconsistencies. Reputable manufacturers pay close attention to details, ensuring every component matches the original specifications. Look for precise fitting, smooth transitions between pieces, and minimal imperfections—all hallmarks of a well-remanufactured part.

Additionally, check the material composition, especially in vehicle paint repair cases. Original equipment manufacturer (OEM) parts have specific formulations, and skilled restorers can replicate these during car restoration processes. The color, texture, and finish should align perfectly with the vehicle’s original paint job. Moreover, authentic remanufactured collision parts often include serial numbers or unique identifiers that allow for easy cross-referencing and verification, enhancing trust in their provenance within the vehicle repair process.

Testing Methods for Quality Assurance

When it comes to ensuring the quality and authenticity of remanufactured collision parts, rigorous testing methods play a pivotal role in the process. These tests go beyond simple visual inspections, delving into the material’s composition, structural integrity, and performance capabilities. Advanced technologies like X-ray fluorescence spectroscopy and ultrasonic testing are employed to detect even microscopic imperfections or variations from the original specifications. By simulating real-world conditions, these methods ensure that remanufactured parts meet the same stringent quality standards as new ones.

Moreover, reputable collision repair centers integrate comprehensive quality assurance protocols into their workflows. This includes meticulous documentation of each step, from part disassembly to reassembly and final inspection. Reputable facilities also offer car paint services that are meticulously matched to the original manufacturer’s specifications, ensuring a seamless finish that enhances the overall aesthetics and value of the vehicle. For instance, fender repair experts utilize advanced computer-aided design (CAD) software to precisely measure and replicate the original contour, guaranteeing both visual perfection and structural soundness.

When purchasing remanufactured collision parts, it’s crucial to verify authenticity to ensure safety and quality. By understanding key indicators and employing testing methods, consumers can make informed decisions. This enables them to navigate the market effectively, ensuring they acquire genuine, high-quality components for their vehicles. Remember that a little extra diligence can go a long way in protecting your investment and maintaining optimal vehicle performance.